Cnc Software Programs

The best software for someone new to CNC is Windows Notepad or another text editor. Read the control manual and become familiar with the code syntax it requires to make it do what you want it to do. Start with simple stuff, programming a toolchange, a rectangle, a circle, drill a hole, etc. Becoming familiar with G code syntax (especially the particular dialect your control requires) is pretty important.

There are a few lower cost CAM systems that are pretty powerful and easy to use, but troubleshooting a program is a h3ll of a sight easier if you can pick the code it posts apart. That said, I use Alibre Design for 3D modeling and Alibre CAM (a plugin made by MecSoft derived from VisualMill, their very capable relatively low cost CAM software) to do my design and CNC programming. Another popular and very capable product at the lower midrance is OneCNC.

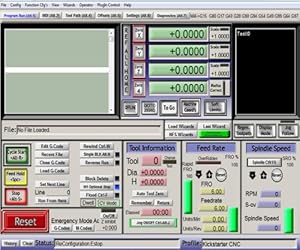

It'll give you an idea of how it all fits together. CAD CAM Software: CNC Machine Programming. CAD and Solid Modeling Software: Drawing Creation. CAM Software: Drawings to G-Codes. Mann Mera Table No 21 Song Download Free. A Word About File Formats. Carving Software. Conversational CNC Programming Software: Quick and Easy GCode Without CAD or CAM.

If you purchase a high enough level of their CAM product, it includes a CAD software. If you want to spend more than that (say in the $10,000 to $15,000 range) there are the industry standards, SolidWorks or SolidEdgefor CAD and say MasterCAM or Gibbs for CAM (to name a few, there are a bunch of similar products out there that people are having success with). Does the control have any sort of conversational programming? Some of the conversational languages are pretty powerful, too. Still, it is best in the long run to learn G code since most controls speak some form of it. The best software for someone new to CNC is Windows Notepad or another text editor. Read the control manual and become familiar with the code syntax it requires to make it do what you want it to do.

Start with simple stuff, programming a toolchange, a rectangle, a circle, drill a hole, etc. Becoming familiar with G code syntax (especially the particular dialect your control requires) is pretty important. There are a few lower cost CAM systems that are pretty powerful and easy to use, but troubleshooting a program is a h3ll of a sight easier if you can pick the code it posts apart. That said, I use Alibre Design for 3D modeling and Alibre CAM (a plugin made by MecSoft derived from VisualMill, their very capable relatively low cost CAM software) to do my design and CNC programming. Download Autodesk Inventor 2013 Full Crack 64 Bit. Another popular and very capable product at the lower midrance is OneCNC. If you purchase a high enough level of their CAM product, it includes a CAD software. If you want to spend more than that (say in the $10,000 to $15,000 range) there are the industry standards, SolidWorks or SolidEdgefor CAD and say MasterCAM or Gibbs for CAM (to name a few, there are a bunch of similar products out there that people are having success with).